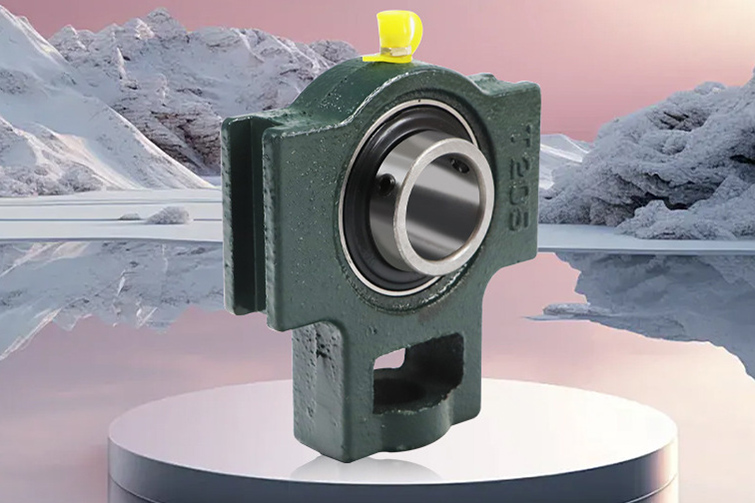

Common Cage Structures and Materials in Mounted Spherical Ball Bearings

Mounted spherical ball bearings, also known as insert bearings or bearing units with housings, are widely used in agricultural machinery, conveyors, fans, and textile equipment due to their ease of installation and self-aligning capabilities. One of the critical internal components of these bearings is the cage (or retainer), which plays a vital role in guiding and spacing the rolling elements (balls) and ensuring smooth rotation. The design and material of the cage directly affect the bearing’s performance, durability, and suitability for various environments.

Below is an overview of the common cage structures and materials used in mounted spherical ball bearings:

Common Cage Structures

a. Pressed Steel Cage

- Structure: This cage is made by stamping thin steel sheets and shaping them into a form that holds the balls in position.

- Features: High strength and dimensional stability Good resistance to deformation under high-speed or high-load conditions Cost-effective and widely used in standard applications

- Applications: General-purpose machinery, conveyors, and light to moderate load environments.

b. Nylon (Polyamide) Cage

- Structure: Molded from reinforced nylon or polyamide resin, sometimes fiber-reinforced.

- Features: Lightweight and quiet during operation Excellent resistance to vibration and shock Good self-lubricating properties, reducing friction and heat generation

- Limitations: Not suitable for high-temperature environments (typically up to 120°C)

- Applications: Agricultural machinery, textile machines, and applications requiring quiet and smooth performance.

c. Brass Cage

- Structure: Machined from solid brass or sometimes die-cast.

- Features: High mechanical strength Excellent wear resistance Superior performance in high-speed and high-temperature applications

- Applications: Heavy-duty industrial equipment, high-speed machinery, or harsh environments.

Conclusion

The cage structure and material in a mounted spherical ball bearing play a critical role in determining the bearing’s suitability for different working conditions. Pressed steel cages are favored for their versatility and strength, nylon cages are ideal for low-noise and vibration-sensitive environments, while brass cages are used in high-performance or extreme conditions.

When selecting a bearing, understanding the operating environment—such as temperature, load, speed, and exposure to contaminants—is essential to choosing the appropriate cage design and material. Proper selection ensures reliability, longevity, and optimal performance of the bearing system.