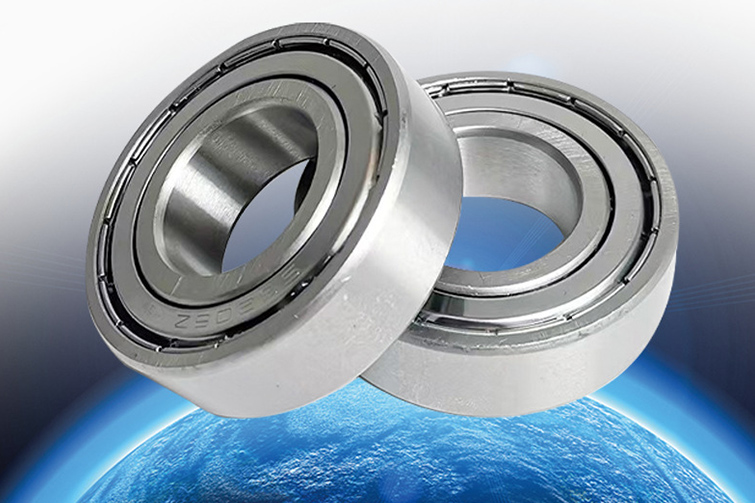

Structural Features of Stainless Steel Deep Groove Ball Bearings

Stainless steel deep groove ball bearings are widely used in applications that require high precision, corrosion resistance, and durability. These bearings are structurally similar to standard deep groove ball bearings but offer enhanced performance in specific environments due to the material used. Below are the main structural characteristics that define stainless steel deep groove ball bearings:

1. Inner and Outer Rings

The inner and outer rings of stainless steel deep groove ball bearings are typically made from high-quality stainless steel, such as AISI 440C or similar alloys. These rings have raceways that form continuous grooves, allowing the balls to rotate smoothly with minimal friction. Stainless steel enhances corrosion resistance, making the bearings suitable for humid, wet, or chemically aggressive environments.

2. Ball Elements

The rolling elements (balls) are also made of stainless steel and are precisely manufactured to maintain dimensional accuracy and surface smoothness. These balls are evenly spaced to minimize friction and allow for high-speed rotation. Their corrosion-resistant nature ensures a longer service life even in challenging conditions.

3. Cage (Retainer)

The cage, or retainer, holds the balls at equal distances and ensures uniform load distribution. In stainless steel deep groove ball bearings, the cage may be made of stainless steel, reinforced nylon, or brass depending on the application. Stainless steel cages are preferred in high-temperature or chemically aggressive settings.

4. Seals or Shields

To protect the internal components from contaminants such as dust, moisture, or debris, these bearings are often equipped with rubber seals (designated with a suffix like -2RS) or metal shields (e.g., -ZZ). Sealed bearings provide better protection and require less maintenance, while shielded versions allow for higher speed performance with limited protection.

5. Deep Grooves

The raceways of deep groove ball bearings are designed with deep, uninterrupted grooves. This structure allows them to support radial loads and moderate axial (thrust) loads in both directions. The deep grooves also ensure better alignment and operational stability under dynamic conditions.

6. Corrosion Resistance

One of the primary advantages of using stainless steel is its inherent resistance to rust and corrosion. This makes these bearings ideal for use in food processing machinery, medical equipment, marine applications, and other areas where exposure to moisture or chemicals is common.

7. Precision and Noise Control

Stainless steel deep groove ball bearings are manufactured to tight tolerances, which ensures quiet operation and minimal vibration. This makes them suitable for applications that require both high precision and low noise, such as electric motors and precision instruments.

Conclusion

Stainless steel deep groove ball bearings combine the versatility of standard deep groove ball bearings with the added benefits of corrosion resistance and durability. Their structural features make them suitable for a wide range of industrial and commercial applications, especially in harsh or clean environments where traditional bearings may fail. Understanding these features helps engineers select the right bearing for optimal performance and reliability.